19 May Irrigation manager is on the move

Despite the past two days of passing showers, May has been an incredibly hot dry month on the farm. We are lucky to have a robust irrigation system that we have established over the years, but that system doesn’t function without the work of an irrigation manager. That person this season is Justin Seelaus, and he’s had a busy month with extremely hot temperatures and a lack of rain.

The average rainfall for our area for May is around 4 inches. So far we have received a little less than an inch this month- and that was all in one day. Despite the steady supply of water provided to them since transplant, spring crops are certainly suffering due to the extreme heat. Our sugar snap peas are looking pretty pitiful, despite the attention we have lavished on them over the past month. However, the heat-loving cucumbers and summer squash and tomatoes are growing in leaps and bounds.

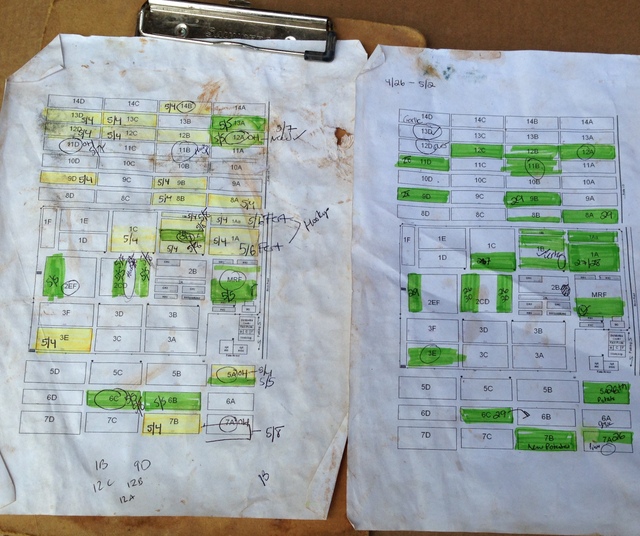

This time of year is the peak of transplanting for the season- Justin must hustle to keep the baby plants watered when they are their most vulnerable. And with every new planting, a new field gets added to the irrigation schedule. After an initial soaking in, the goal is to water everything two times a week, for at least 2 hours at a time. This mimics about a half inch of rainfall with each watering.

Justin hooks up drip irrigation on the greenhouse heirloom tomatoes as the crew transplants them into the ground.

“One of the things I really love about being irrigation manager, is knowing I have a direct correlation with the plant success (or doom!) and seeing noticeable growth from day to day, especially in crops like cucumbers and summer squash. ” Justin’s job takes him around the farm on a daily basis. “I get to walk the fields almost everyday, I have an intimate connection with each bed and each crop.”

The majority of our crops are watered with drip irrigation, though we still do a fair share with overhead irrigation, which is delivered through above ground pipes and sprinkler heads. Overhead is used on bare ground crops like potatoes, beets, carrots, radishes and turnips. We use sprinkler heads called the R2000 Windfighters- aptly named because they actually function better with a little wind, critical on the hill tops of Blooming Glen.

From a water conservation standpoint the value of the drip tape cannot be underestimated. Buried a few inches underground, and then covered by the black mulch, the drip allows us to use less water to achieve the results we need.

On the left is a field of potatoes on bare ground, irrigated with overhead sprinklers. On the right is a field of potatoes planted on black plastic mulch, irrigated with drip, and covered with row covers. Notice the size difference of the plants.

Each bed, depending on the crop, gets one or two lines of drip. Cucumbers, tomatoes, squash and melons, 1 line; fennel, kale, and onions, 2 lines. So far this season we have laid 16 rolls of drip tape- that’s close to 23 miles of drip irrigation bringing life sustaining water to our plants that Justin has to monitor and repair if needed.

You may spot Justin cruising the farm on the orange ATV we call “The Shark”, one of the perks of the job. This Del Val grad is constantly on the go, turning water on and off in various fields, accompanied by his bucket of parts- connectors, end plugs, tools to build the manifold, knife, screwdriver, cordless drill, pvc fittings, pressure regulators and pressure gauges.

The drip lines are laid by the tractor drawn implement, but they all come together out of the fields into a manifold that Justin builds, and each manifold gets a pressure regulator. The drip lines function best at 12 psi, but the well is set at 50 psi, the optimum pressure to run our Windfighter sprinkler heads. Pressure regulators are used to bring the pressure down to keep from blowing the drip lines out.

Even though the drip lines are buried a few inches in the soil, they can still get holes in them during the transplanting process. A certain amount of Justin’s time is spent repairing leaks. The biggest culprit, besides tractors running over the manifolds, is driving in stakes for trellised crops, of which we have about 2 acres. This activity can quickly make swiss cheese out of the drip lines if the crew isn’t careful.

Another crucial job of the irrigation manager is fertigating, which is running fertilizer through the drip irrigation system. Right now Justin has been fertigating the strawberries with a certified organic fertilizer that contains seaweed, calcium, and other vital nutrients that aid in bloom. We also utilize a fish and kelp blend to provide support to the growth of our leafy green crops.

According to Justin one of the biggest challenges of the job is finding the sweet spot where you are running as much water as you can without overburdening the system to the point where it loses efficiency. “It’s something I have learned by observing pressure changes in the lines as more water is turned on.”

The ground is still a bit damp from the rain we had a few days ago, but soon enough Justin will be heading out to hook up the drip lines on the newly planted field of sweet peppers, juggling his daily water schedule between the regular farm jobs like harvesting and weeding, and heading home at the end of the day to empty his pockets of all the miscellaneous drip connectors he’s accumulated over the day.

Post and photos by Tricia Borneman, Blooming Glen farmer and co-owner. Tricia and her husband Tom have been farming together since 2000. Blooming Glen Farm is entering its 10th season bringing high quality certified organic vegetables, herbs, fruits and cut flowers to our local community. Tricia is passionate about food, art and nature and the intersection and expression of all three.

Sorry, the comment form is closed at this time.